Quality Control

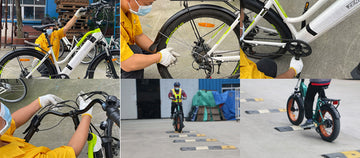

Incoming Quality Control

The inspector will eliminate products and their accessories that do not meet relevant technical standards and ensure that every accessory used in production is a qualified product.

Quality control process

Carry out fatigue tests on the frame, including testing the frame cracking, fracture, and shock absorption function. Only after that, we start painting frames and spraying brand logos. For the sample ebike, we will test its function, performance, and appearance, and must obtain an experimental report. The factory will organize mass production when the sample ebike is qualified. During the assembly process, the bicycles will be adjusted and reworked immediately, if there are any problems in braking, shifting, and driving angle.

Final Quality Control

he ebikes need to be finally inspected and tested when the assembly is completed. Visual inspection. Check the frame if there are scratches and if the saddle, chain, tire, and connector are not properly assembled. Function inspection. We will do a riding test to ensure that the electric bicycles can flexibly go straight and turn around, the LCD display shows all parameters normally, the intelligence pedal can be normally shifted, the motor works without abnormal sound, and the spokes and tires are correctly installed.

Performance inspection. Speed test, climbing test, brake test, shock absorption test on the bicycle will be carried out to ensure superior performance.-